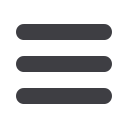

ELECTRICAL

insulation, high

mechanical resistance

LISI AUTOMOTIVE

INSULATING SCREW

EQUIPPING HYBRID

VEHICLES

The rapid development of hybrid and fully electric vehicles

generatesnewconstraints in termsof fasteners. Theassembly

of organs operating at different electrical potentials, made

necessary to optimize the space in the vehicle, is one of these

new issues. To meet those requirements, LISI AUTOMOTIVE

hasdevelopeda longM7 (100mm), class 10.9screw, insulatedon

the non-threaded part by thermoplastic overmolding. Various

laboratory tests have qualified the electrical resistance of

the insulating protection (breakdown potential) as well as its

resistance to corrosion in various environments.

LISI MEDICAL

PROTOTYPING

GAINING AGILITY

This year LISI MEDICAL developed a new rapid prototyping

cell at its Neyron site. Consisting of a milling center, a

turning-milling center and a lathe, the unit optimizes the

industrialization of mass production parts, reserves a

non-production area for developments and debugging, and

accelerates qualification processes. It offers the ability to

produce low volumes without

disturbing the “high-runners” and

allows the site to gain agility.

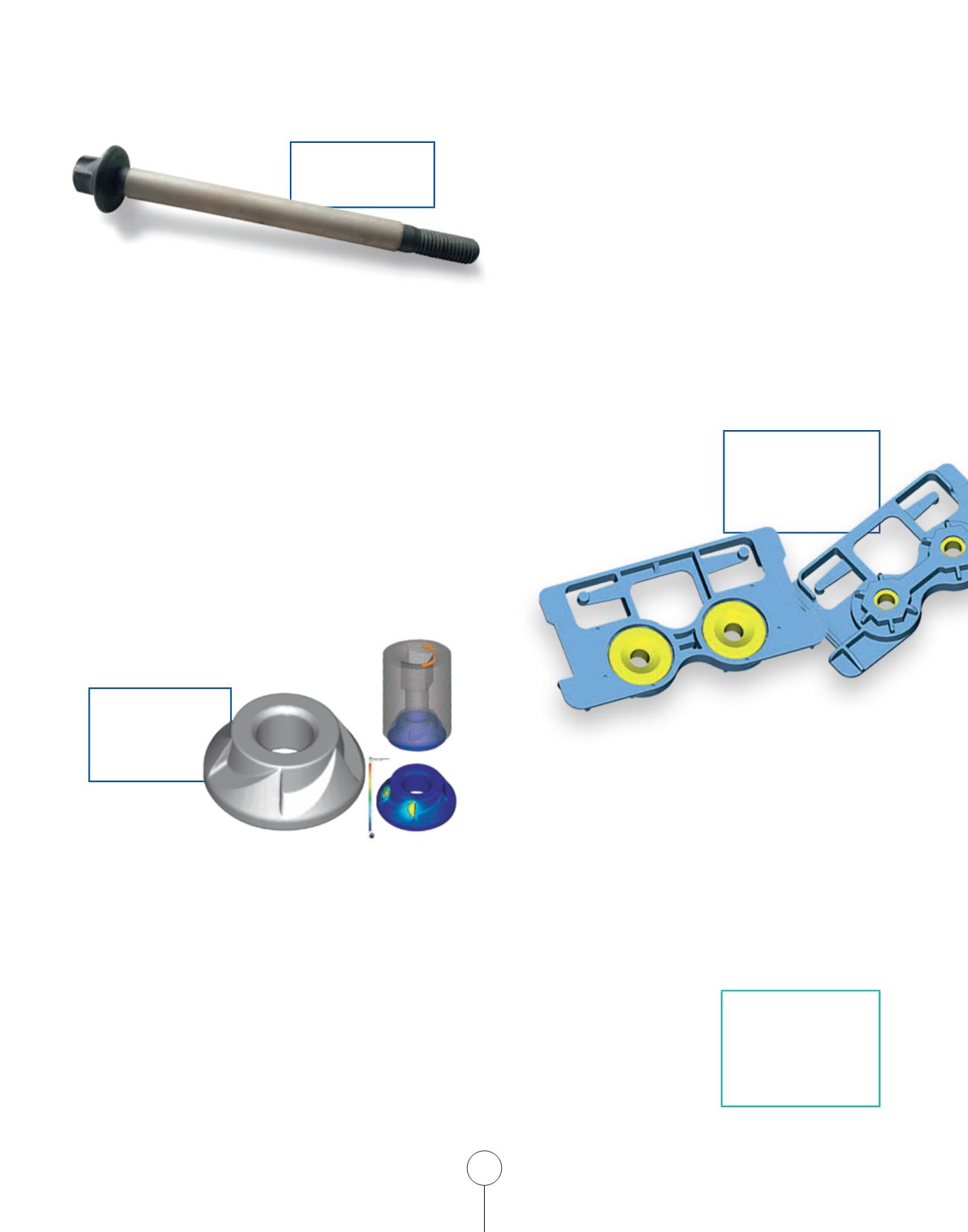

LISI AUTOMOTIVE

METALLOPLASTIC

SOLUTIONS

LIGHTER VEHICLES

Capitalizingon itsdual expertise in low-alloy steel cold-heading

and plastic injection technologies, LISI AUTOMOTIVE offers

metalloplastic solutions that lighten automotive vehicles and

contribute to the reduction of greenhouse gas emissionswhile

reducingproductioncosts. Thedesignof the injectedpartof the

newdoor latches allows for seamless installation. This system,

which maintains the mechanical robustness of the function,

reduces the assembly time at the manufacturers and offers

aweight reduction of 50%compared to an all-metal solution.

LISI AUTOMOTIVE

TAMPER-PROOF NUT

INCREASING SECURITY

I n o r de r to mee t t he demand o f manu f ac t u r e r s ,

LISI AUTOMOTIVE has developed a nut whose geometry and

mechanical properties make it easy to screw but impossible

to unscrew quickly without the right tool. The design and

characteristics of this tamper-resistant nut, which enhances

the safety of the vehicle interior, have been validated by

digital simulation. An initial version of the nut, proposed in

low alloy steel with M6 tapping, is now available and can be

offered in various diameters. A tamper-proof screw version,

based on the same principle, is under development.

3915%

This is the production

time devoted to

development and

industrialization projects

absorbed by this newunit

SECURING

sensitive elements

of the vehicle

cabin and ease of

implementation

50%

weight gain

compared to “all metal”

solutions +mechanical

robustness and time saving

during assembly