INNOVATION

INNOVATION

I

PRODUCTS

LISI AEROSPACE

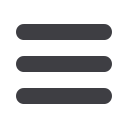

TiAl

FORGING THE MOST

COMPLEX MATERIALS

TiAl (Titanium-Aluminum alloy) is an intermetallic, lightweight material that can

withstand high temperatures. It gradually replaces the Nickel-based superalloys

used in the hot parts of engines, such as turbine blades, while weighing only

half as much. Very difficult to deform because of its low ductility, its industrial

processing is very complex. To circumvent this obstacle, LISI AEROSPACE has

developed an alternative so-called “hot dies” forging technology at its Forges de

Bologne plant. It maintains the productivity of conventional forgingwhile achieving

a metallurgical quality close to that of isothermal forgings (forging installation

operating at 1,250/1,300°C), particularly in terms of microstructure homogeneity

and external health of the parts. By reducing production costs to levels acceptable

by the market, this innovation will promote the rise of this exceptional material on

new generation engines.

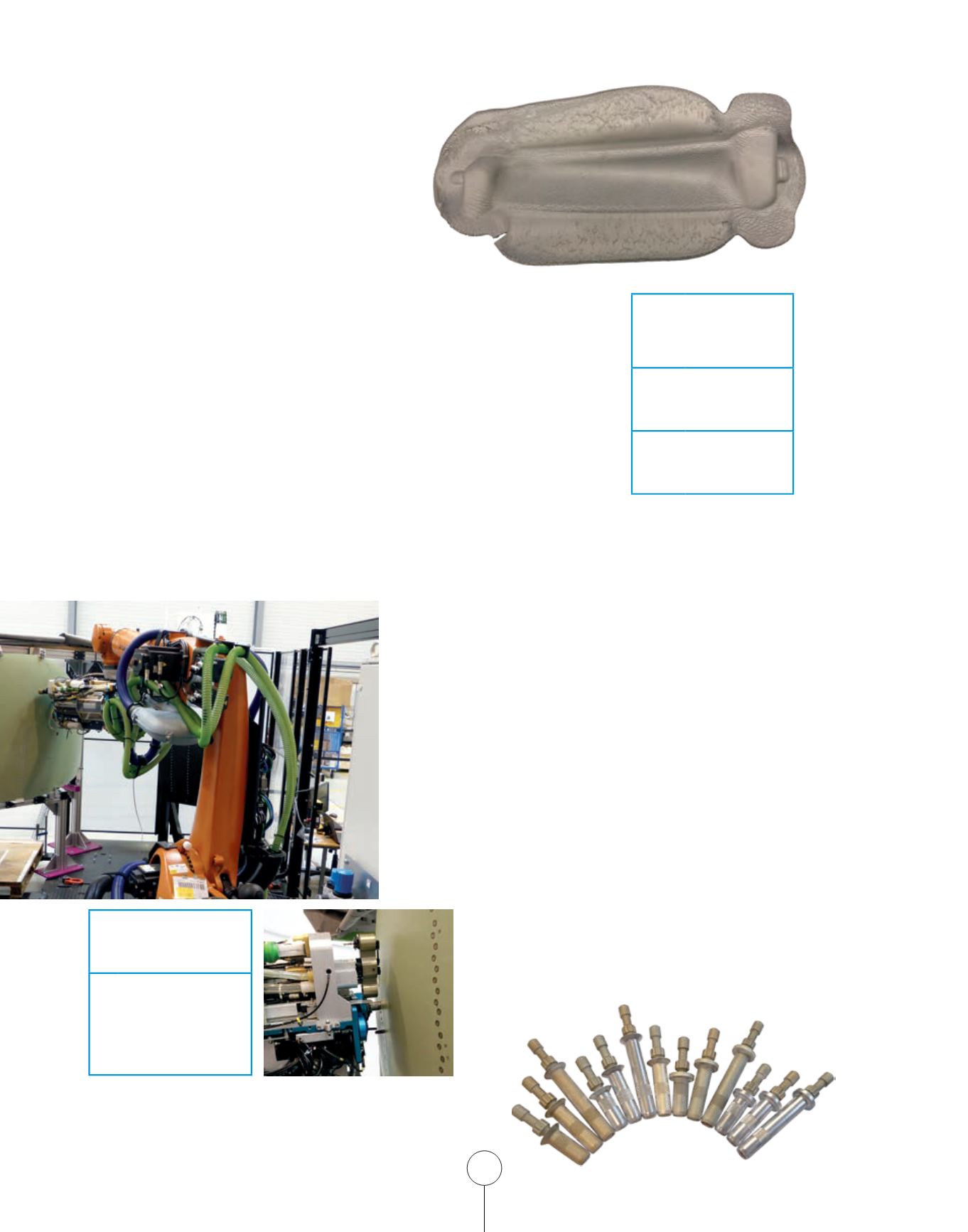

LISI AEROSPACE

ROBOID PROJECT

VALIDATING THE TECHNOLOGIES

OF THE FUTURE

To improve competitiveness and ensure high production rates, aircraft

manufacturers are now focusing their efforts on the automation and

efficiency of assembly processes. Since 2011, LISI AEROSPACEhas initiated

the development of automated structural assembly technologies through

the LISI@OneSide program. On this basis, in collaboration with Dassault

Aviation, which contributes its expertise as aircraft manufacturer, and

thanks to the support of the General Directorate of Civil Aviation (DGAC), we

have built the ROBOID collaborative project. This industrial demonstration

project aims to demonstrate the relevance of the LISI@OneSide automated

assembly system with the new OPTIBLIND ™ blind fasteners and CLY62

temporary fasteners. Implemented in an environment that

is representative of actual production conditions, ROBOID

proves the robustness and economic benefits of this assembly

technology and validates this major technological leap in aircraft

production.

1

proven automated

assembly solution from

one side of the structure

100%

robotic sequences

(drilling, sealant

application, assembly

and control)

36-20Kg

on an engine thanks to

TiAl turbine blades

X

4

Productivity gain

over isothermal

forge

X

2

Static strength

of forgedTiAl vs.

moldedTiAl