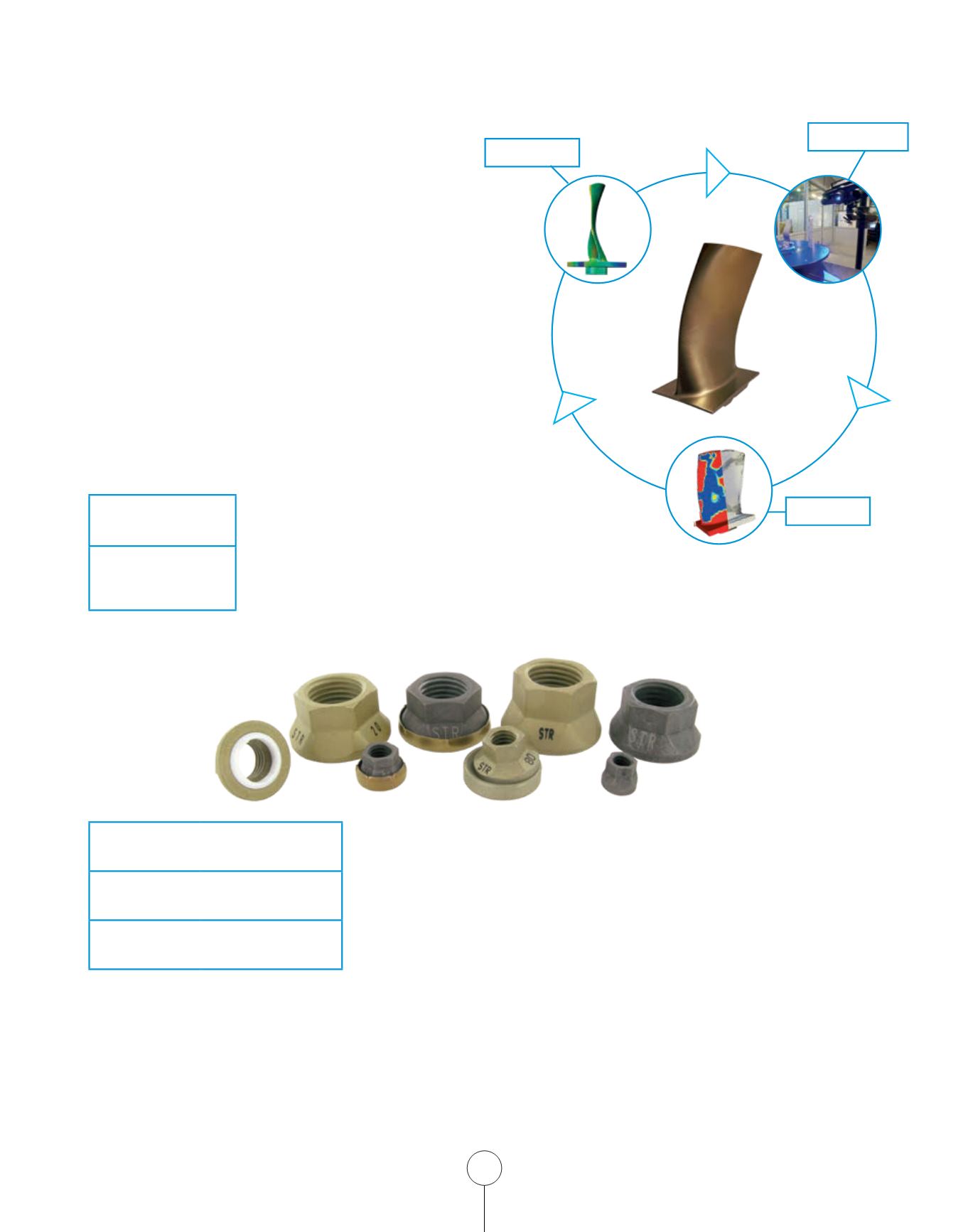

LISI AEROSPACE

STARLITE™ TITANIUM NUTS

MULTIPLE APPLICATIONS

Launched in 2010, LISI AEROSPACE’s lightweight, composite-compatible

STARLITE™ nuts product line has been further expanded to better meet the

requirements of the North Americanmarket. These titaniumnuts, whose strength

is comparable to steel nuts, are perfectly compatible with composite structures

and titanium fasteners. The existing range for STL™, HI-LITE™ and HI-LOK™

systems is now extended to seal nuts, captive and self-aligning nuts and a new

HI-KOTE™ 2 solid lubricant film option has been validated. The STARLITE™ range

already equipsmany newgeneration aircraft and provides a competitive advantage

for programs in development.

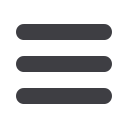

LISI AEROSPACE

DIGITAL SIMULATION

GAINING PERFORMANCE

In order to accelerate the development of new products

and optimize production processes, which constitute

the core of operational performance, LISI AEROSPACE

invests continuously in digital simulation tools and skills.

The acquisition of a 3D scanner, combined with numerical

simulations of the blade forming process produced at the

Marmande site, enabled the development of manufacturing tools

by digital iterations alternatively to physical tests. This was made

possible thanks to the level of prediction that could be achieved

with this numerical chain. This method, developed by plant teams

and R&D engineers, was used for the first time this year for forming a

LEAP compressor blade. This step opens up major prospects in terms of

time and cost optimization, both for the production

and development cycles.

37CORRELATION

3DMETROLOGY

SIMULATION

200Kg

weight saving on

a long‑haul plane

REDUCED

inventories: replaces

many existing references

COMPATIBLE

with composite

structures

ELIMINATING

rework and scrap

REDUCING

development time

and costs