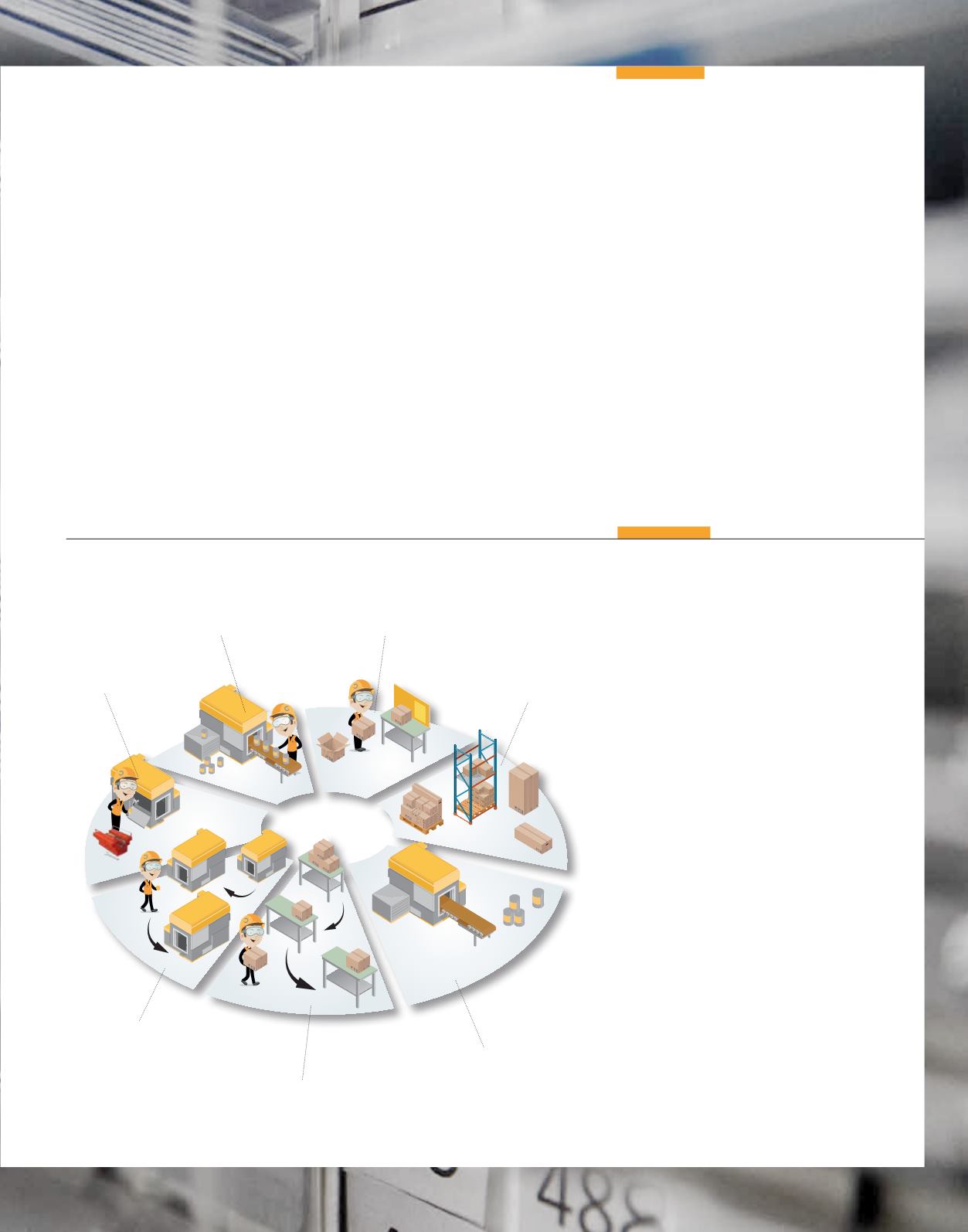

GembaWalk

toavoidwaste

GembaWalk is an essential tool of Lean

Management, and lets operators better

understandtheirwork,stepbacktoassesswhat

theyhave todo, identify the risksandhighlight

possible sources of waste. This optimization

method through observation, for which

trainingwas providedduring the LEAPBasics

stage,allowseachemployee to takeadifferent

lookathisorherdailywork.

Improvingworkingconditions

TheGembaWalks, whichhave beenprepared

duringpreparationof theworking areas, help

the fight against waste and increased safety

foroperators. It isoneof thecentral featuresof

LEAP inorder toworkunder thebest possible

working conditions while not harming the

environment.

This approach makes our activities more

ordered,more reliableandmorecompetitive.

TRI

OVERPRODUCTION

TREATMENT

PROCESSES

STOCKs

REJECTS

INVENTORY

MOVEMENTS

TRANSPORT

WAITINGTIME

LISI 2013

23

Asourceofsavings

for theGroup

The first resultsof theLEAPstrategydeployedoperatively in2013canalready

be seen. Setting up PSM (Problem SolvingManagement) has facilitated a

reductionof at least 60%of recurrenceson the factory floor, involvingavery

real improvement inservice levels.

Firstresultsatalllevels

The deployment of SMED (SingleMinute Exchange of Die) work areas, a

method foroptimizing the timeneeded tochangeaproduction runor tools,

and 5S,which increases precision inworking, has facilitated a reduction in

HSE risks by optimizing ergonomics and getting rid of obstacles in traffic

flows.Timesforchangeofaproductionrunhavebeenreducedby50%,ashas

theconsumptionof tools, involvingasavingof1millioneuros in investments.

Added value for m2 increased more than 25%. Workshops involved in

optimizingwork flowshavebeenableto improve leadtimesandreducework

inprogress.

+25%

increase inaddedvalue

persquaremeter

€

1

m

ofsavings

in investments

200

improvementprojects

completed in2013